21

2025

-

04

Understanding Chain Driven Conveyor Belts: Key Benefits and Applications

Chain driven conveyor belts are an integral part of modern industrial operations, providing efficient material handling solutions across various sectors. Their unique design and robust construction make them ideal for numerous applications, from manufacturing to distribution centers. This article will discuss the key benefits and operational aspects of chain driven conveyor belts, helping you unde

Chain driven conveyor belts are an integral part of modern industrial operations, providing efficient material handling solutions across various sectors. Their unique design and robust construction make them ideal for numerous applications, from manufacturing to distribution centers. This article will discuss the key benefits and operational aspects of chain driven conveyor belts, helping you understand their relevance in today’s industrial landscape.

One of the primary advantages of chain driven conveyor belts is their ability to transport heavy loads with ease. Unlike traditional belt systems that may struggle under significant weight, chain driven systems utilize a series of interlocking chains and sprockets. This design enhances the structural integrity and durability of the conveyor, allowing it to handle substantial materials without compromising performance. This is particularly beneficial in environments where heavy machinery, bulk materials, and large items must be moved efficiently.

Additionally, chain driven conveyor belts offer superior traction compared to conventional belt systems. The chain mechanism provides a positive drive, minimizing slip and ensuring consistent movement along the conveyor line. This characteristic is essential in high-speed operations where timing and precision are critical to the overall productivity of the system. By maintaining a steady flow of materials, businesses can optimize their production processes, resulting in better output and reduced downtime.

Another significant benefit of chain driven conveyor belts is their versatility. These systems can be designed to accommodate a variety of materials, from raw components to finished products. They can also be configured in multiple layouts, including straight, inclined, or even complex curves, making them adaptable to the specific needs of a facility. This flexibility allows for seamless integration into existing workflows, enhancing overall operational efficiency.

Maintenance is also a crucial consideration when evaluating conveyor systems. Chain driven conveyor belts typically require less frequent maintenance than traditional belt systems, primarily due to their rugged build and fewer wear components. Regular lubrication and inspection will ensure optimal performance and longevity, reducing the likelihood of unexpected breakdowns that can disrupt operations.

Finally, the cost-effectiveness of chain driven conveyor belts should not be overlooked. While initial investments may vary, the long-term benefits, including reduced maintenance costs and increased productivity, can lead to significant savings over time. Businesses that prioritize efficiency and reliability in their material handling processes will find this technology to be a worthy addition to their operations.

In conclusion, chain driven conveyor belts present a viable solution for industries seeking to enhance their material handling capabilities. With their ability to manage heavy loads, provide reliable traction, and adapt to various layouts, these systems are a key asset in maximizing efficiency and productivity in industrial settings. Understanding these advantages can guide businesses in making informed decisions about their material handling solutions.

One of the primary advantages of chain driven conveyor belts is their ability to transport heavy loads with ease. Unlike traditional belt systems that may struggle under significant weight, chain driven systems utilize a series of interlocking chains and sprockets. This design enhances the structural integrity and durability of the conveyor, allowing it to handle substantial materials without compromising performance. This is particularly beneficial in environments where heavy machinery, bulk materials, and large items must be moved efficiently.

Additionally, chain driven conveyor belts offer superior traction compared to conventional belt systems. The chain mechanism provides a positive drive, minimizing slip and ensuring consistent movement along the conveyor line. This characteristic is essential in high-speed operations where timing and precision are critical to the overall productivity of the system. By maintaining a steady flow of materials, businesses can optimize their production processes, resulting in better output and reduced downtime.

Another significant benefit of chain driven conveyor belts is their versatility. These systems can be designed to accommodate a variety of materials, from raw components to finished products. They can also be configured in multiple layouts, including straight, inclined, or even complex curves, making them adaptable to the specific needs of a facility. This flexibility allows for seamless integration into existing workflows, enhancing overall operational efficiency.

Maintenance is also a crucial consideration when evaluating conveyor systems. Chain driven conveyor belts typically require less frequent maintenance than traditional belt systems, primarily due to their rugged build and fewer wear components. Regular lubrication and inspection will ensure optimal performance and longevity, reducing the likelihood of unexpected breakdowns that can disrupt operations.

Finally, the cost-effectiveness of chain driven conveyor belts should not be overlooked. While initial investments may vary, the long-term benefits, including reduced maintenance costs and increased productivity, can lead to significant savings over time. Businesses that prioritize efficiency and reliability in their material handling processes will find this technology to be a worthy addition to their operations.

In conclusion, chain driven conveyor belts present a viable solution for industries seeking to enhance their material handling capabilities. With their ability to manage heavy loads, provide reliable traction, and adapt to various layouts, these systems are a key asset in maximizing efficiency and productivity in industrial settings. Understanding these advantages can guide businesses in making informed decisions about their material handling solutions.

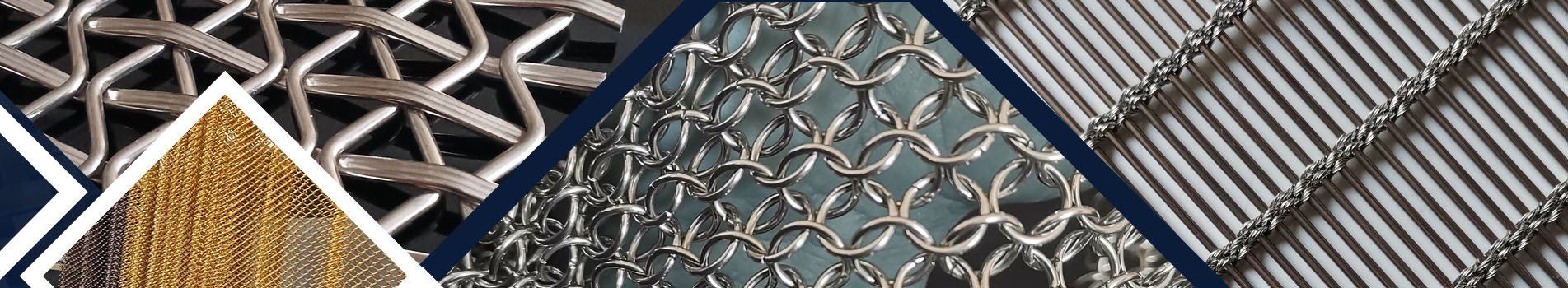

Chain Driven Conveyor Belt

Related news