19

2024

-

04

Enhancing Product Quality with Compound Balanced Belts in Industrial Equipment

**Introduction** In the competitive world of industrial manufacturing, product quality is a top priority for businesses looking to stay ahead of the curve. One key factor in achieving high-quality products is the use of the right equipment, including compound balanced belts. These innovative belts offer a range of benefits that can help improve product quality and overall efficiency in industrial

**Introduction**

In the competitive world of industrial manufacturing, product quality is a top priority for businesses looking to stay ahead of the curve. One key factor in achieving high-quality products is the use of the right equipment, including compound balanced belts. These innovative belts offer a range of benefits that can help improve product quality and overall efficiency in industrial settings. In this article, we will explore the advantages of using compound balanced belts in industrial equipment and how they can enhance your manufacturing processes.

**What are Compound Balanced Belts?**

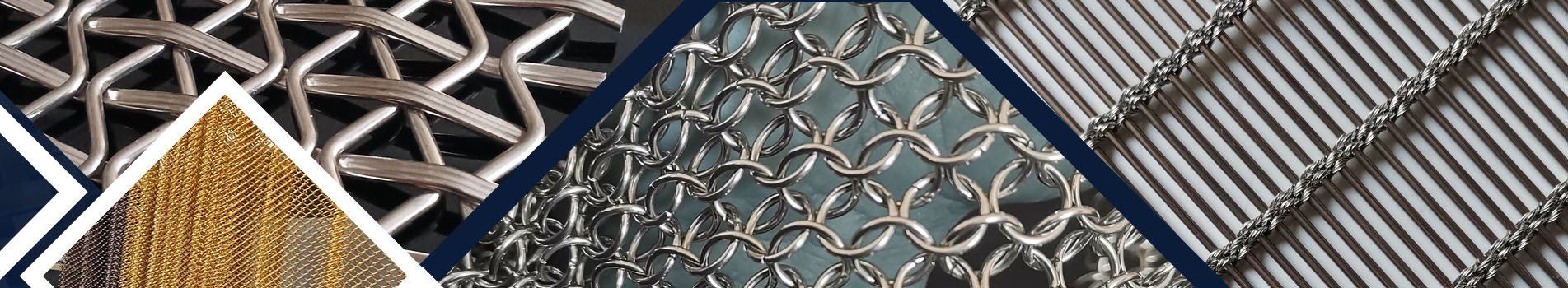

Compound balanced belts are specially designed conveyor belts that consist of a series of interlocking metal links. These belts are known for their durability, flexibility, and strength, making them ideal for a wide range of industrial applications. The unique construction of compound balanced belts allows for smooth and efficient movement of products along the production line, reducing the risk of damage or defects.

**Benefits of Using Compound Balanced Belts**

1. **Improved Product Quality**: One of the primary benefits of using compound balanced belts is the enhanced product quality they provide. The smooth and consistent movement of products along the conveyor belt reduces the risk of damage, ensuring that finished products meet high-quality standards.

2. **Enhanced Efficiency**: Compound balanced belts are designed to optimize production processes, allowing for faster and more efficient manufacturing. This increased efficiency can lead to higher output and reduced production costs, ultimately benefiting your bottom line.

3. **Reduced Downtime**: The durability of compound balanced belts means that they require minimal maintenance and are less prone to wear and tear. This results in reduced downtime for repairs and replacements, keeping your production line running smoothly and consistently.

4. **Versatility**: Compound balanced belts are highly versatile and can be customized to meet the specific needs of your production process. Whether you are working with heavy-duty materials or delicate products, compound balanced belts can be tailored to ensure optimal performance.

**How to Implement Compound Balanced Belts in Your Industrial Equipment**

Integrating compound balanced belts into your industrial equipment is a straightforward process that can yield significant benefits. Start by consulting with a trusted supplier or manufacturer to determine the best type of compound balanced belt for your specific application. Consider factors such as product weight, speed, and size when selecting the appropriate belt for your needs. Once you have chosen the right belt, work with your supplier to ensure proper installation and maintenance to maximize performance and longevity.

**FAQs**

1. What industries can benefit from using compound balanced belts?

Compound balanced belts are widely used in industries such as food processing, automotive manufacturing, and electronics production, among others.

2. Are compound balanced belts suitable for high-speed production lines?

Yes, compound balanced belts are designed to withstand high speeds and can effectively transport products along fast-moving production lines.

3. How do compound balanced belts compare to traditional conveyor belts?

Compound balanced belts offer superior durability, flexibility, and efficiency compared to traditional conveyor belts, making them a preferred choice for many industrial applications.

4. Can compound balanced belts be customized for specific production needs?

Yes, compound balanced belts can be tailored to meet the unique requirements of your production process, ensuring optimal performance and efficiency.

5. What maintenance is required for compound balanced belts?

Compound balanced belts require minimal maintenance due to their durable construction, but regular inspections and cleaning can help prolong their lifespan and ensure consistent performance.

**Conclusion**

In conclusion, compound balanced belts are a valuable asset for industrial equipment, offering a range of benefits that can significantly improve product quality and efficiency in manufacturing processes. By incorporating these innovative belts into your production line, you can experience enhanced productivity, reduced downtime, and increased profitability. Consult with a trusted supplier to explore the options available and start reaping the rewards of using compound balanced belts in your industrial equipment.

In the competitive world of industrial manufacturing, product quality is a top priority for businesses looking to stay ahead of the curve. One key factor in achieving high-quality products is the use of the right equipment, including compound balanced belts. These innovative belts offer a range of benefits that can help improve product quality and overall efficiency in industrial settings. In this article, we will explore the advantages of using compound balanced belts in industrial equipment and how they can enhance your manufacturing processes.

**What are Compound Balanced Belts?**

Compound balanced belts are specially designed conveyor belts that consist of a series of interlocking metal links. These belts are known for their durability, flexibility, and strength, making them ideal for a wide range of industrial applications. The unique construction of compound balanced belts allows for smooth and efficient movement of products along the production line, reducing the risk of damage or defects.

**Benefits of Using Compound Balanced Belts**

1. **Improved Product Quality**: One of the primary benefits of using compound balanced belts is the enhanced product quality they provide. The smooth and consistent movement of products along the conveyor belt reduces the risk of damage, ensuring that finished products meet high-quality standards.

2. **Enhanced Efficiency**: Compound balanced belts are designed to optimize production processes, allowing for faster and more efficient manufacturing. This increased efficiency can lead to higher output and reduced production costs, ultimately benefiting your bottom line.

3. **Reduced Downtime**: The durability of compound balanced belts means that they require minimal maintenance and are less prone to wear and tear. This results in reduced downtime for repairs and replacements, keeping your production line running smoothly and consistently.

4. **Versatility**: Compound balanced belts are highly versatile and can be customized to meet the specific needs of your production process. Whether you are working with heavy-duty materials or delicate products, compound balanced belts can be tailored to ensure optimal performance.

**How to Implement Compound Balanced Belts in Your Industrial Equipment**

Integrating compound balanced belts into your industrial equipment is a straightforward process that can yield significant benefits. Start by consulting with a trusted supplier or manufacturer to determine the best type of compound balanced belt for your specific application. Consider factors such as product weight, speed, and size when selecting the appropriate belt for your needs. Once you have chosen the right belt, work with your supplier to ensure proper installation and maintenance to maximize performance and longevity.

**FAQs**

1. What industries can benefit from using compound balanced belts?

Compound balanced belts are widely used in industries such as food processing, automotive manufacturing, and electronics production, among others.

2. Are compound balanced belts suitable for high-speed production lines?

Yes, compound balanced belts are designed to withstand high speeds and can effectively transport products along fast-moving production lines.

3. How do compound balanced belts compare to traditional conveyor belts?

Compound balanced belts offer superior durability, flexibility, and efficiency compared to traditional conveyor belts, making them a preferred choice for many industrial applications.

4. Can compound balanced belts be customized for specific production needs?

Yes, compound balanced belts can be tailored to meet the unique requirements of your production process, ensuring optimal performance and efficiency.

5. What maintenance is required for compound balanced belts?

Compound balanced belts require minimal maintenance due to their durable construction, but regular inspections and cleaning can help prolong their lifespan and ensure consistent performance.

**Conclusion**

In conclusion, compound balanced belts are a valuable asset for industrial equipment, offering a range of benefits that can significantly improve product quality and efficiency in manufacturing processes. By incorporating these innovative belts into your production line, you can experience enhanced productivity, reduced downtime, and increased profitability. Consult with a trusted supplier to explore the options available and start reaping the rewards of using compound balanced belts in your industrial equipment.

compound balanced belt

Related news